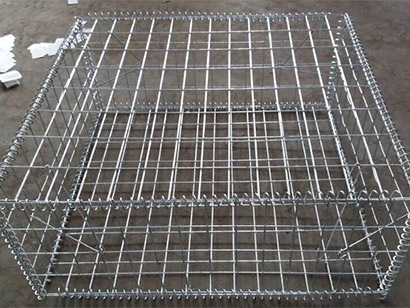

According to different ways of fabrication ,mainly wire mesh can be divided into two types, welded wire mesh and woven wire mesh , woven wire mesh apertures and wires can be various ,thousands of specs ,Compared to woven type , welded type has it’s own advantages, It has bigger apertures (openings) ,The wires welded at each intersection giving the mesh strength and the capability of maintaining its integrity under stress, in other words , it is firm, steady ! it is widely used in different construction projects , since it is cheaper and quicker fabricated , also easy cut and shape forming ,welded mesh in stainless steel is free of corrosion ,can survival very long time in acid ,hot ,wet situation.

Stainless steel welded wire mesh is welded from a series of transverse and longitudinal stainless wires at right angles, usually square, with a firm weld at each crossing of transverse and longitudinal wire. The stainless weld mesh with 0.25-1 inch square openings is also known as stainless steel hardware cloth, welded wire mesh is used in a wide range of applications, such as plaster mesh, machine guards, animal fences, flower fences, window guards, access fences, and poultry cages, etc.